Don’t Rush Quality: The Truth About Quick Garage Floor Installs

In the fast-paced world of garage floor coatings, “one-day” installation services are marketed as quick, easy, and convenient. But what most homeowners don’t realize is that many of these companies are cutting corners. To save time and increase profit, they often skip critical steps like moisture mitigation. That shortcut puts the entire floor coating system at risk.

One of the most serious missteps is applying polyaspartic or polyurea coatings directly to concrete without first using a moisture-mitigating epoxy primer. Although it may save a few hours on installation day, it severely compromises the durability and integrity of the coating. Big time.

Are the flakes used in your system decorative or functional?

The flakes in the flooring system serve multiple functional purposes beyond their aesthetic appeal. They significantly enhance slip resistance, especially in areas prone to moisture or spills, creating a safer environment for walking and driving. Additionally, the inclusion of flakes contributes to the overall durability, making the surface more resistant to wear and tear over time. When mica stone flakes are incorporated, the floor’s impact resistance and hardness are further enhanced, allowing it to withstand heavy impacts and abrasions.

Adding mica stone flakes not only boosts the floor’s strength but also elevates its visual appeal. Their reflective qualities give the surface a distinctive, attractive appearance. Ultimately, integrating mica flakes results in a resilient, virtually indestructible flooring solution that combines safety, durability, and aesthetic appeal.

Overall, the flakes combine both aesthetic and functional benefits, making them a versatile component in the coating system.

Are your coatings VOC-compliant and environmentally safe?

Yes, our garage floor coating products are ZERO VOC and 100% solids, making them environmentally safe and VOC-compliant. We focus on using eco-friendly products that meet all current regulations, ensuring a safe, sustainable, and high-quality solution for your garage or commercial space. Our zero VOC coatings provide excellent durability and performance without compromising environmental responsibility.

Can garage floor coatings be installed in cold or humid climates?

Yes, at GarageFloorCoating.com, our coating systems are specially engineered to perform in a wide range of environments—including extreme heat, freezing temperatures, and high humidity. No matter the climate, our industrial-grade products deliver long-lasting durability and reliable performance year-round.

We use industrial-grade resins manufactured exclusively by Eco-CorFlex Industrial Polymers, which are formulated to cure properly even in challenging environmental conditions. Whether it’s high humidity or colder temperatures, our experienced installers adjust installation techniques and cure schedules to ensure a proper bond and long-lasting durability.

Unlike many “one-day” coating companies that rely on fast-curing polyaspartics vulnerable to moisture interference, we always start with a moisture-mitigating epoxy primer, allowing our coatings to perform reliably in garages across all regions and seasons.

No shortcuts. No seasonal limitations. Just beautiful, high-performance floors—installed right the first time.

Can your system be applied to older concrete that is damaged and stained?

Absolutely, at GarageFloorCoating.com, our ultra thick moisture mitigating industrial-grade coating systems are specifically designed to be applied not just to older concrete, but also to heavily damaged, contaminated or previously coated surfaces.

Whether your slab is decades old, has minor cracks, surface imperfections, or even more severe damage, we have the expertise and proprietary products to restore it. Our process includes thorough surface preparation (like diamond grinding and moisture testing), structural and cosmetic repairs, and the application of a multi layer moisture-mitigating coating system to ensure a durable, long-lasting bond.

We don’t just coat new concrete, we specialize in revitalizing and protecting older, worn, and even previously failed concrete floors and coatings. It’s what sets GarageFloorCoating.com apart.

What Leading Coating Manufacturers Say

Respected manufacturers throughout the resinous flooring industry consistently emphasize the same core principles. These include General Polymers by Sherwin-Williams, Corotech by Benjamin Moore, Sika, Tnemec, BASF, Euclid Chemical, Stonhard, and Eco-CorFlex Industrial Polymers.

They all agree that proper moisture testing must be conducted before coating any concrete surface. In addition, they recommend using a 100 percent solids moisture vapor barrier epoxy primer prior to applying polyaspartic or polyurea topcoats.

This recommendation exists for a reason. Polyaspartics and polyureas cure extremely fast, leaving little time for the material to penetrate the concrete surface. Without that deep bond, the coating becomes vulnerable to moisture vapor rising from within the slab. The result is a range of problems including bubbling, blistering, peeling, or full delamination.

Even companies that produce polyaspartic and polyurea products themselves, such as ArmorPoxy and VersaFlex, make it clear that these products are not intended for use as primers on bare concrete. They are topcoats only.

What Industry Standards Require

This position is also supported by industry standards. Organizations like ASTM International, the American Concrete Institute, the International Concrete Repair Institute, and AMPP (formerly SSPC and NACE) all set clear expectations for coating systems.

These standards call for thorough moisture testing of the slab, surface preparation that meets Concrete Surface Profile guidelines, and the application of epoxy-based vapor barriers before any polyurea or polyaspartic products are used.

ASTM F3010, in particular, defines the standards for controlling moisture vapor beneath resinous flooring. Skipping this step not only leads to a higher likelihood of coating failure but also typically voids any warranty that may have been offered.

The Risk of Skipping the Primer

When contractors skip the moisture-mitigating primer, moisture vapor can build up beneath the coating. This creates hydrostatic pressure that weakens the bond between the concrete and the coating. Since fast-curing products like polyaspartic and polyurea do not absorb into the concrete well, the bond is already limited. Add trapped moisture, and the failure rate rises dramatically.

In residential garages, especially in regions like Michigan where seasonal changes affect ground moisture, this kind of failure can happen within months. Many one-day installers exclude moisture-related issues from their warranties altogether. If they do offer moisture protection, the allowable limits are often too low to be meaningful.

For example, polyaspartic and polyurea coatings applied directly to concrete generally cannot handle more than three to four pounds of moisture vapor emission per one thousand square feet per twenty-four hours, as measured by ASTM F1869. In terms of relative humidity, that’s about seventy-five to eighty percent, according to ASTM F2170. Most garage floors exceed these levels, especially during spring and fall in Michigan.

Do you offer color and design customization?

At GarageFloorCoating.com, we offer extensive color and design customization to match your style, space, and vision.

Choose from a wide range of flake blends, metallics, solid colors, and our exclusive Mica Stone blends, a proprietary option only available through GarageFloorCoating.com. Whether you’re looking for something subtle and classic or bold and modern, our customizable design options let you create a floor that’s uniquely yours.

Our goal isn’t just durability; it’s delivering a floor that looks as stunning as it performs.

How does diamond grinding improve coating adhesion?

We use 800 lbs Lavina diamond grinding equipment to properly prepare the concrete surface and ensure long-term adhesion of our multi-layer coating systems.

This process is critical because:

✅ It creates an ideal surface profile – Diamond grinding removes the smooth surface layer of concrete typically called the “Cream Layer” not only does it produce a textured finish (profile), by removing this natural protective concrete layer it

At GarageFloorCoating.com, proper surface preparation isn’t an afterthought—it’s the foundation of a beautiful, long-lasting floor.

How does GarageFloorCoating.com handle cracks in the concrete?

At GarageFloorCoating.com, our crack repair system goes far beyond cosmetic patching, it’s engineered for permanent structural reinforcement.

While most companies (especially “one-day” installers) use fast-setting fillers that shrink, crack, or fail over time, we take a comprehensive and advanced approach:

✅ Deep-penetrating, moisture mitigating repair materials – We use high-performance moisture mitigating urethane epoxy hybrid-based menders that chemically bond to the concrete permanently and prevent cracks from reappearing beneath the coating.

✅ Crack stitching with carbon fiber – For structural or recurring cracks, we implement a crack stitching repair system. This involves embedding multiple carbon fiber stitches directly into the concrete, dramatically increasing tensile strength and preventing future movement or separation.

✅ Integrated into a full preparation system – Our crack repairs are just one part of a broader surface preparation process that includes diamond grinding, moisture mitigating, and a multi-layer, full-broadcast coating system for unmatched durability.

In short, we don’t just fill cracks—we stabilize them for life, using the same reinforcement techniques found in commercial and industrial concrete repair.

When you choose GarageFloorCoating.com, you’re choosing professional-grade repairs, not shortcuts.

How long does a full-chip epoxy garage floor coating last?

At GarageFloorCoating.com, our full-chip Moisture Mitigation Epoxy Polyaspartic floor coating systems are designed for maximum durability and longevity.

When properly installed with our multi-layer, moisture-mitigating system and maintained as recommended, your coating can last 30 years or more. Unlike “one-day” polyurea polyaspartic systems that skip critical moisture mitigation, our industrial-grade coatings include a 100% solids vapor barrier primer, full-broadcast chip application, and 2 100% solids polyaspartic topcoats, thus eliminating the possibility of peeling, staining, hot tire lift, and UV degradation.

In fact, we’re so confident in our systems that we offer a lifetime warranty against any type of peeling (aka delamination) even due to moisture-related issues—something you simply won’t find elsewhere.

Want it to last decades? Then skip the shortcuts. Go full chip. Go GarageFloorCoating.com.

Can garage floor coatings be installed in cold or humid climates?

Yes, at GarageFloorCoating.com, our coating systems are specially engineered to perform in a wide range of environments, including extreme heat, freezing temperatures, and high humidity. No matter the climate, our industrial-grade products deliver long-lasting durability and reliable performance year-round.

We use industrial-grade resins manufactured exclusively by Eco-CorFlex Industrial Polymers, which are formulated to cure properly even in challenging environmental conditions. Whether it’s high humidity or colder temperatures, our experienced installers adjust installation techniques and cure schedules to ensure a proper bond and long-lasting durability.

Unlike many “one-day” coating companies that rely on fast-curing polyaspartics vulnerable to moisture interference, we always start with a moisture-mitigating epoxy primer, allowing our coatings to perform reliably in garages across all regions and seasons.

No shortcuts. No seasonal limitations. Just beautiful, high-performance floors—installed right the first time.

Why This Is a Problem

Moisture levels in concrete slabs are rarely stable. Across the United States—and certainly in Michigan—it is common for garage floors to exceed five to ten pounds MVER or relative humidity above eighty-five percent. Without a proper moisture-mitigating primer, the coating is almost guaranteed to fail.

In contrast, true moisture vapor barrier epoxies like Eco-CorFlex MME can handle up to one hundred percent RH and more than twenty pounds MVER. These products allow contractors to offer meaningful warranties, even in high-moisture environments.

So when one-day installers say they offer moisture protection, that claim often does not hold up under real-world conditions if it only took a day to install. And the fine print is really what gets you.

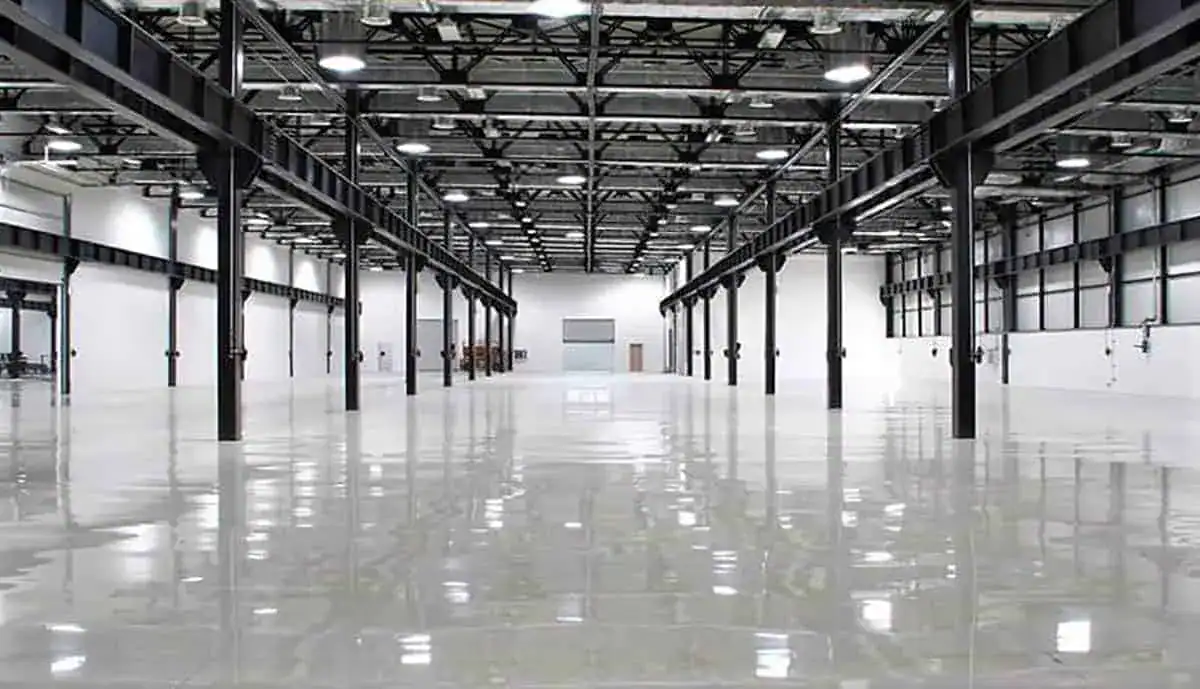

How We Install Garage Floor Coatings

At GarageFloorCoating.com, we don’t cut corners. We test every concrete slab for moisture, no matter what. Every floor we install includes a moisture-mitigating epoxy primer as the foundational layer. This is standard, not optional.

Because we follow manufacturer guidelines and industry standards, we are able to offer real warranties. Our systems are built to handle actual moisture levels found in Michigan garages—not just ideal lab conditions.

Need a concrete floor coating?

Request a Free Quote

Oops! We could not locate your form.

Final Word

If a contractor tells you they can coat your garage floor in a day, ask how they handle moisture. If they skip testing or say the primer isn’t necessary, that is a red flag. What sounds like a faster install is often a future failure in progress.

Choose a company that takes the time to do it right. A floor that lasts starts with preparation that cannot be skipped.